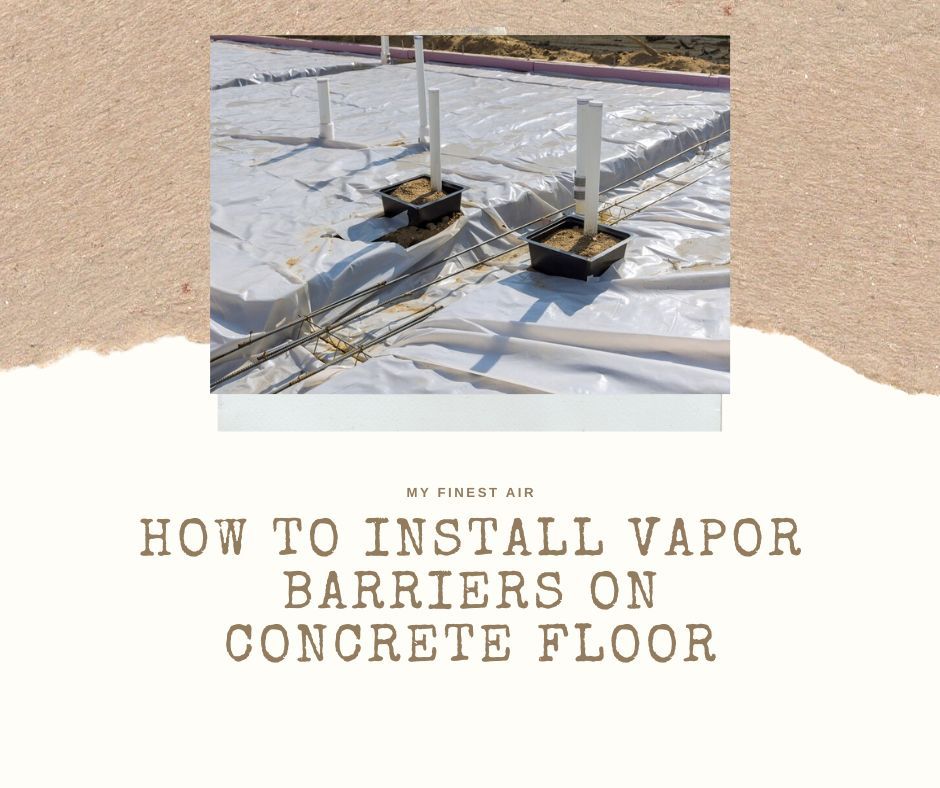

How To Install Vapor Barriers On Concrete Floor? Complete Guide

Vapor barrier installation is a difficult task that necessitates using equipment not commonly found in the home. Because thoroughness is crucial, we'll go through each stage in greater detail below.

Why is Vapor Barrier Important?

Vapor barrier installation is important on concrete floors to prevent moisture and air infiltration. Moisture can cause damage to the concrete floor, while air infiltration can cause condensation and mold growth.

A vapor barrier will help maintain the concrete floor's structural integrity while preventing moisture and air infiltration. Vapor barriers are available in various materials, including metal, plastic, and fiberglass.

What is Vapor Retarder?

A vapor retarder is a type of insulation used in cold climates to help keep the inside of your home warm. Vapor retarders are made from fiberglass, cellulose, and other natural compounds.

When installed correctly, these materials can help slow the movement of heat through your walls and ceilings. This can help to keep your home at a comfortable temperature all year round.

When choosing a vapor retarder, it is important to consider the climate where you live. Some vapor retarders work in cold climates, while others are designed for warmer climates.

It is also important to consider the insulation you have installed in your home. For example, a vapor retarder may not be necessary if you have fiberglass insulation. Conversely, if you have cellulose or other types of insulation, a vapor retarder may be the best option.

See Also: Is Water Leaking From Air Conditioners Dangerous?

How to Install Vapor Retarder on Concrete Floor

If you're looking to install a vapor barrier on your concrete floor, there are a few things you'll need to do first. Here's how:

To install a vapor barrier on concrete flooring, first, clean the surface of the concrete using a detergent and water mixture. Make sure that any debris has been removed before beginning the installation process.

Next, remove any old sealant or paint from around the perimeter of the flooring using a utility knife or scraping tool. Once all sealant and paint have been removed, apply a layer of silicone caulk around all edges of the flooring, ensuring that all cracks are filled in as well.

1. Measure the area you want to cover. You'll need to calculate the total square footage of the floor, including any areas that may be exposed at the wall or ceiling.

2. Calculate the amount of material you'll need. Typically, vapor barriers require between 18 and 24 inches of material for each foot above the floor. So, if your ceiling is 8 feet high, you'll need at least 128 inches of material (24 inches x 8 feet).

3. Choose a vapor barrier type and size. Several types of vapor barriers are available on the market, so it is important to choose one that will fit your needs and specifications. Some common types include Closed Cell Polyethylene (CCP), Open Cell Polyethylene (OCP), and Polyisocyanurate Foams (PIFs). You'll also want to decide on the barrier size - it typically ranges from 1/4 inch to 3 inches thick.

4. Assemble the materials. Once your supplies are ready, it's time to start assembling the barrier! Begin by cutting the desired amount of CCP or OCP into pieces that will fit along one edge of your wall or ceiling opening - make sure all cuts are straight and even!

Place a piece of insulation over each cut surface, then If the terminating edge isn't exerting enough pressure to hold the vapour barrier in place, seal it softly into the wall and fasten it with a term bar.

5. After you've completed taping off the sides of the vapour barrier, use the seaming tape supplied by the manufacturer to seal the seams.

6. The final stage involves going around and double-checking for any damage or missing locations. If you have extra vapour barrier materials on hand, you can use these to cover and seal the damaged areas with seam tape.

Pros and Cons of Installing Vapor Barrier on Concrete Floor

There are pros and cons to installing a vapor barrier on concrete floors. The pros of installing a vapor barrier include the following:

-The vapor barrier can help protect the floor from moisture and mildew damage.

-A vapor barrier can also help stop concrete from becoming wet and slippery in the winter.

-Vapor barriers can also help reduce noise and heat transfer through the floor.

-The con of installing a vapor barrier is that it can increase the installation cost.

There are many pros and cons to installing vapor barriers on concrete floors. A vapor barrier can help protect the floor from moisture and condensation. However, there are some potential drawbacks to using a vapor barrier on a concrete floor. One disadvantage is that the vapor barrier can make it difficult to install fiberglass insulation over the concrete surface. Additionally, if the vapor barrier becomes wet or damaged, it can create an environment for mold growth.

You can check our guide: How Long Should You Run An Air Purifier - Quality Indicator

Things To Consider While Choosing A Vapor Barrier

Selecting the right vapor barrier for your concrete floor is important to protect it from moisture and other harmful gases and liquids.

There are a few things you'll need to consider when selecting a vapor barrier for your concrete floor:

-The type of vapor barrier material you'll use

-The thickness of the vapor barrier

-The installation method you choose

Here's a look at some of the most common types of vapor barriers and their associated characteristics:

Polyethylene Vinyl Acetate (PVA): PVA is similar to PVM in that it has small, open pores, but it also has an adhesive property that makes it more durable. Although the installation may be slightly more complicated than PVM, PVA offers better protection against moisture and gas leakage.

Conclusion

If you're thinking of installing a vapor barrier on your concrete floor, you should know a few things.

First and foremost, consult with an experienced contractor or architect to ensure that the installation is done correctly and without any potential damage. Second, be prepared to budget for the materials and labor involved in installing a vapor barrier; this task can be pricey.

And finally, always wear protective gear when working with concrete so that you don't encounter any injuries during the installation process.